In today’s competitive landscape, equipment businesses are constantly striving to enhance their operational efficiency and deliver top-notch products and services to their customers. One critical aspect of achieving these goals is maintaining the highest standards of equipment quality through effective inspection processes.

As a leading provider of innovative software solutions for equipment businesses, we bring forth the A365 solution, which encompasses a comprehensive suite of inspection capabilities. This solution stands as a true game-changer for equipment businesses, introducing a transformative approach that fuels productivity, streamlines compliance efforts, and enhances overall customer satisfaction.

With a proven track record of innovation, A365 empowers equipment businesses to optimize their inspection processes comprehensively, ensuring meticulous attention to potential issues.

By leveraging the power of A365, businesses can usher in a new era of operational efficiency, effortlessly meet regulatory requisites, and foster enduring customer confidence and contentment.

Our capabilities offer a comprehensive toolkit tailored to equip equipment businesses with the tools they need to power enhanced inspection levels and facilitate their growth journey.

This suite of features is meticulously designed to streamline the inspection process, bolster equipment reliability, and ensure safety compliance. These functionalities work synergistically to benefit equipment businesses.

A365 for equipment inspections

Scheduled inspections: In the realm of equipment management, regular assessments are pivotal. A365 excels in automating and managing schedules. By proactively identifying potential issues and addressing them before they escalate, businesses can prevent costly breakdowns, ensure optimal equipment performance, and foster an environment of operational reliability.

Inspection faults and observations: Keeping tabs on equipment health is essential. A365 empowers businesses to document any observed faults or anomalies. This documentation forms the basis for targeted maintenance efforts, minimizing downtime, optimizing resource allocation, and bolstering operational efficiency.

Checkpoint rules: Standardization is a cornerstone of effective inspections. CheckPoint rules provided in A365 guide businesses through a consistent and comprehensive process. This systematic approach ensures that no critical aspect is overlooked, resulting in equipment that meets the highest standards of quality and performance.

Mandatory photographs or videos: Visual evidence can be invaluable in assessing equipment conditions. A365 mandates the inclusion of photographs or videos for specific checkpoints, enabling better-informed decision-making by stakeholders. These visual records facilitate accurate diagnosis, streamline team communication, and enhance organizational transparency.

Checklists by equipment type: One size doesn’t fit all in equipment inspections. We recognize this by offering customizable checklists tailored to different equipment types. This adaptable approach ensures that checks are tailored to the unique characteristics and needs of each piece of equipment, effectively optimizing the assessment process.

Checklists by process step: Complexity demands structure. A365 provides checklists organized by process steps, guiding businesses through a sequence of tasks. This feature ensures that no crucial step is missed, enhancing the accuracy and completeness of industries with intricate workflows.

Rental inspections vs. process steps: Equipment rental businesses face distinctive challenges. A365 intelligently distinguishes between rental inspections and internal process steps. This differentiation ensures that it aligns with the context of equipment usage, thus supporting well-informed decision-making and efficient operations.

Service-related inspections/safety checks: Adhering to safety and regulatory standards is paramount. A365 incorporates service-related and safety checks, affirming compliance with industry regulations. This feature not only prevents potential accidents but also nurtures a reputation for safe and responsible operations.

Trade-in inspections: By assessing the condition of returned equipment, businesses can accurately determine trade-in value and anticipate any necessary repairs, thereby facilitating smoother transactions and informed business decisions.

Service reminders- outstanding faults & observations: Timely action is the essence of maintenance. A365 offers service reminders based on outstanding faults and observations. This proactive approach ensures that issues are promptly addressed, preventing further deterioration and ensuring uninterrupted equipment performance.

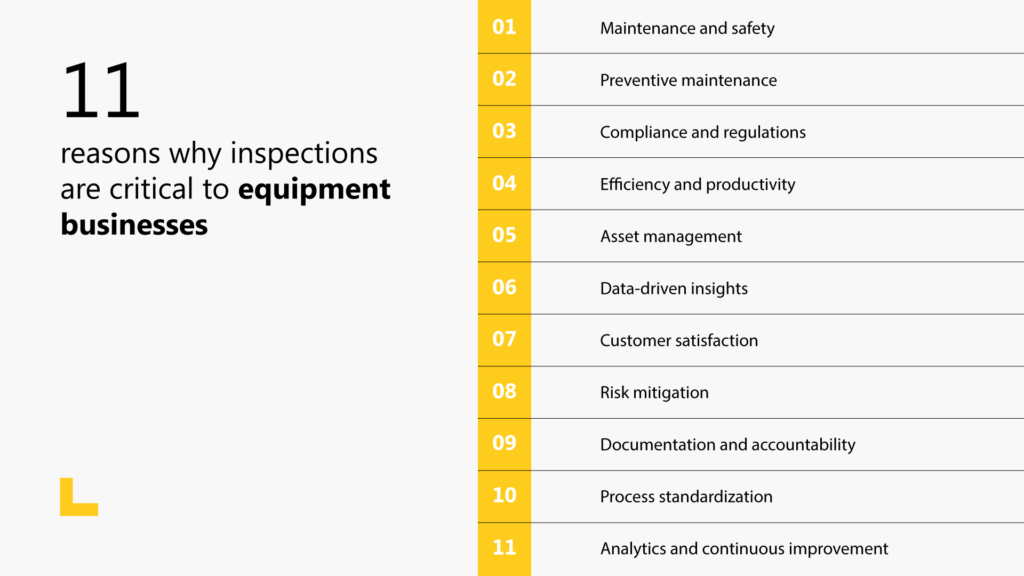

11 reasons why inspections are critical to equipment businesses

Inspection processes play a pivotal role in equipment businesses due to their multifaceted significance in ensuring safety, reliability, and operational excellence. Regular inspections are crucial to identify potential faults, weaknesses, and wear-and-tear that could compromise equipment performance, safety, and longevity.

By proactively addressing these issues through systematic processes, equipment businesses can minimize downtime, reduce the risk of accidents, and extend the lifespan of their assets.

Moreover, it serves as a key component of compliance with industry regulations and standards. Many sectors, such as construction, manufacturing, and transportation, are bound by stringent regulations governing the safety and reliability of equipment. Non-compliance can lead to severe consequences, including legal penalties and reputational damage.

Robust inspection processes enable businesses to stay in adherence to these regulations, mitigating legal risks and reinforcing their reputation as responsible and safety-conscious operators.

Furthermore, it provides a comprehensive view of equipment condition over time, facilitating data-driven decision-making, optimizing maintenance schedules, and allocating resources efficiently. In essence, inspections are the cornerstone of effective equipment management, ensuring optimal performance, safety, and regulatory compliance.

Related reading: The importance of digitized equipment inspections

Here are 11 reasons why inspections are critical to equipment businesses:

Maintenance and safety: Regular inspections are crucial for identifying wear and tear, potential faults, or safety hazards in equipment. A software helps schedule and prepare documentation systematically, ensuring that equipment is well-maintained and safe for operation.

Preventive maintenance: Regular inspections enable businesses to adopt a preventive maintenance approach. By identifying issues early, businesses can address them before they escalate into costly breakdowns, minimizing downtime and reducing repair expenses.

Compliance and regulations: Many industries have strict regulations and safety standards that equipment must adhere to. Inspection software helps equipment businesses stay compliant by facilitating proper documentation, and ensuring that equipment meets regulatory requirements.

Efficiency and productivity: Efficient inspections reduce operational disruptions caused by unexpected breakdowns. By maintaining equipment in good working condition, businesses can enhance productivity and operational efficiency.

Asset management: Software tracks the condition and history of the equipment, providing businesses with insights into their assets’ performance over time. This information informs decisions about repairs, replacements, and equipment retirements.

Data-driven insights: Data collected over time can be analyzed to identify patterns and trends. These insights help businesses make informed decisions about maintenance strategies, equipment purchasing, and resource allocation.

Customer satisfaction: Well-maintained equipment improves customer experience, whether you’re renting out equipment or providing services. Reliable equipment reduces the risk of delays, breakdowns, or accidents, enhancing customer satisfaction.

Risk mitigation: In industries where equipment failure could lead to accidents or injuries, software plays a critical role in risk mitigation. By ensuring equipment is in optimal condition, the software helps prevent accidents and their associated legal and financial consequences.

Documentation and accountability: Digital inspection records provide a clear trail of maintenance activities and any repairs performed. This documentation can be essential for warranty claims, audits, and demonstrating due diligence.

Process standardization: Inspection software allows you to define and enforce standardized procedures. This consistency ensures that inspections are thorough and complete, regardless of who performs them.

Analytics and continuous improvement: By analyzing inspection data, businesses can identify recurring issues, areas of improvement, and opportunities for innovation in equipment design or maintenance processes.

If you’re interested in delving deeper into our functionalities tailored for equipment businesses, we invite you to explore more information on our website. Alternatively, reach out to us here to speak to one of our consultants about your equipment business needs.