Advancements in technology and digitization have made paper-based inspections a thing of the past, driving more automotive businesses to adopt Digital Vehicle Inspection (DVI) processes that streamline operations to achieve higher efficiencies.

Digital vehicle inspection in its entirety eliminates the traditional paper-based approach that is typically time-intensive and has low levels of efficiency and accuracy.

Digital vehicle inspection is facilitated through software applications ideally hosted in the cloud, making it more practical and seamless than its paper predecessor. It empowers technicians with automation tools that run on laptops, tablets, and mobile devices to access and store data when performing tests, measurements, and inspections.

The digital inspection software improves efficiency and refines how the service center communicates with its customers. It also helps workshops and service centers address vehicle problems that the customers experience using detailed information and supporting photographs and videos, making the entire inspection process effective and time efficient for both the customer as well as the service center.

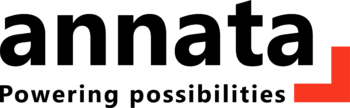

A typical scenario with paper-based vehicle inspections:

A customer brings their vehicle to the service center and details their issues to a customer service representative. This representative shares this information with the technician who performs the necessary inspections and details the solutions on paper. This paper is handed to the representative who then relays the information to the customer manually by walking over to them in the waiting lounge or via a call.

The customer may request additional information and cost breakdown to ensure they make an informed decision before giving their approval to perform the repairs. The representative compiles the additional information from the technician and builds a quotation for the repairs which is then shared with the customer for approval.

Not only is the entire process inefficient, but it also requires multiple communication touchpoints and a prolonged waiting period that could agitate a customer and increase the time a vehicle is left in the service center.

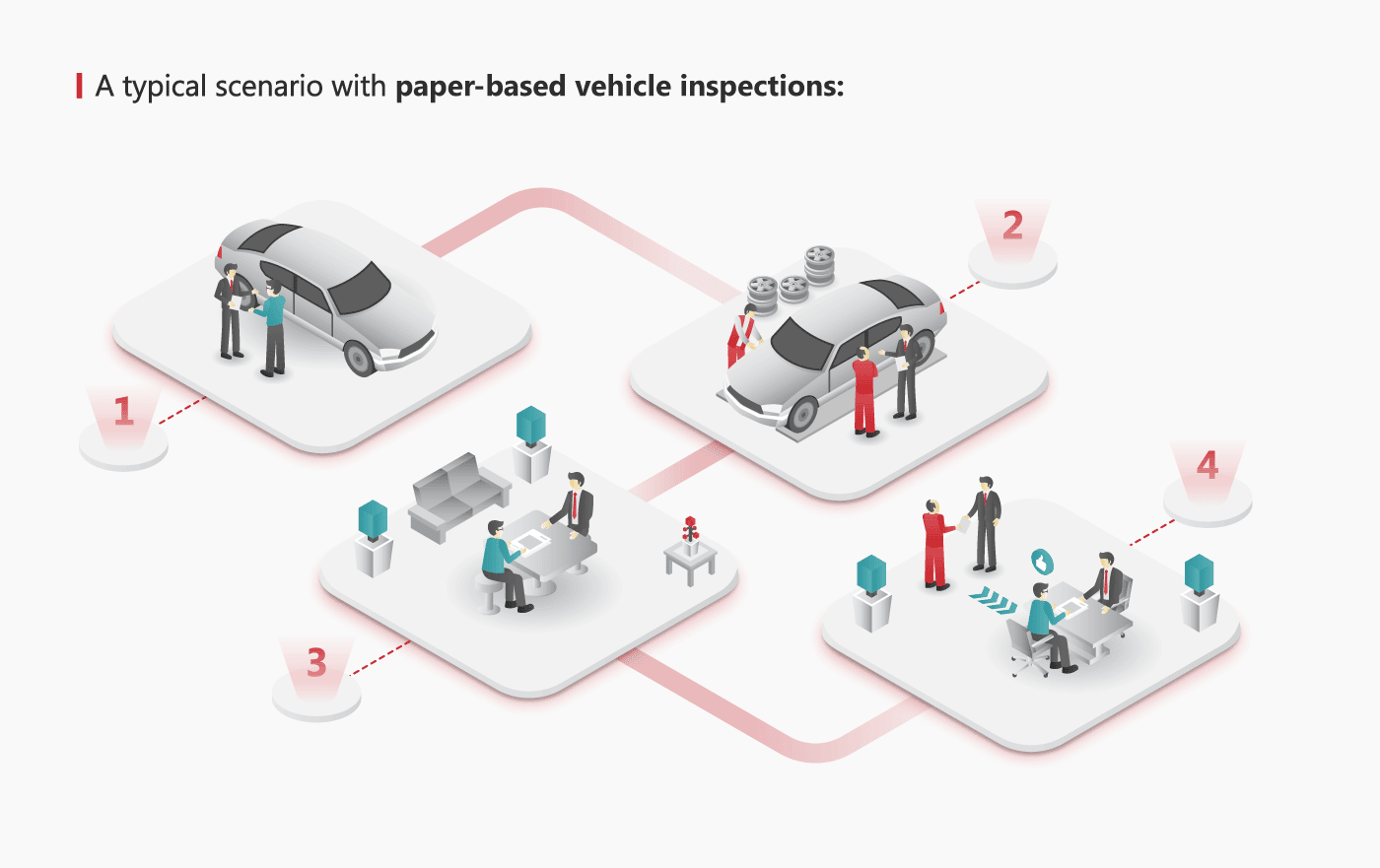

A typical scenario with digital vehicle inspection:

A customer brings their vehicle to the service center and details their issues to a customer service representative. The representative enters these issues into the system which is immediately available to the technician. The technician performs the inspection and completes a report with recommended repairs supported by photos and videos of faulty parts and a quotation.

The technician sends the report to the customer who reviews the recommendations and gives approval for repairs. The technician can then provide photos and video proof of the completed repairs and send updates to the customer to notify them of the completion status and when they can collect their vehicle.

This process is a tangible and transparent approach to enabling the customer to approve repairs with photo and video evidence empowering them to make informed decisions. The customer also enjoys the convenience, experience, and control of reviewing and approving the repairs on their schedule.

Advantages of digital vehicle inspection software in your service center

There are many reasons why Digital Vehicle Inspection software is a must-have in every Service Center, but if we boil them down to the top five reasons DVI will boost automotive Service Center efficiency, they are the following:

- Anticipate vehicle repairs

Digital inspections allow the capture and recording of data in real time. This data is compiled and analyzed to not only diagnose the immediate vehicle problems but to spot faulty parts patterns and anticipate potential vehicle issues.

Through predictive analytics that leverages artificial intelligence (AI), machine learning (ML), and the internet of things (IoT), Service Centers can raise pre-emptive alerts for vehicle parts failure whilst enabling assessment of wear and the deterioration of vehicle performance.

2. Optimize workflow and increase productivity

Digital vehicle inspection assists technicians in streamlining processes and saves their time as they juggle jobs on the service floor. With on-cloud software, the assigned technicians are instantly prompted the moment a vehicle rolls into the service bay and can access the vehicle’s history as well as current service requests.

Digital inspections enable the assigned technician to have a clear view of what they are working on, without ever leaving the service bay, making inspection easier, speedier, and more reliable all while maintaining standard operating procedures through prescribed job lists available on their mobile device.

It also streamlines the process with the ability to order the parts needed and confirmation of when a part will be in stock.

3. Effective and transparent communication with customers

When it comes to performing repairs, customers tend to be skeptical about the costs of required repairs. Explaining the vehicle issues can also be frustrating as customers do not have a strong understanding of vehicle parts and terminologies. Because of this, customers may assume they are being overcharged.

With a DVI system, however, Service Centers can help their customers feel empowered. Technicians can attach proof of the vehicle problems for the customer to better understand the issue with recommendations and repair cost breakdown provided. This helps customers decide their next steps and ensure they confidently make their decision.

The transparency that DVI provides makes it easier for customers to approve repairs which may increase the workshop’s average repair order but will certainly improve the speed with which a decision to approve the service work is made

4. Custom report building and ease of navigation

Digital vehicle inspection systems enhance every phase of the vehicle inspection process. Service Centers can create a full multi-point inspection template that provides consistent and detailed quality reports enabling technicians to improve their productivity.

Service Centers can also customize their own inspection reports using built-in templates that provide consistent and professional quality checklists that are easy to understand and navigate.

DVI software highlights and explains the critical repairs that require immediate attention. Reports explaining the work necessary generate a higher level of engagement with the customer.

5. Track jobs and increase revenue

With DVI software, technicians’ time spent on each repair can be recorded and analyzed to identify potential areas for efficiency and prioritize which jobs they should work on. The technicians themselves save a lot more time with detailed information made easily accessible to them so that they have an overview of the inspection required based on the reported issues.

This saves time and supports the technician in giving the vehicle immediate attention resulting in a shorter turnaround time. These efficiencies can then be translated to greater profitability and support other key performance indicators. Approved and declined jobs by the customers can also be tracked so that the workshop has a complete customer lifetime history and thus build increased customer loyalty over time.

Annata 365 Inspections for digital vehicle inspections

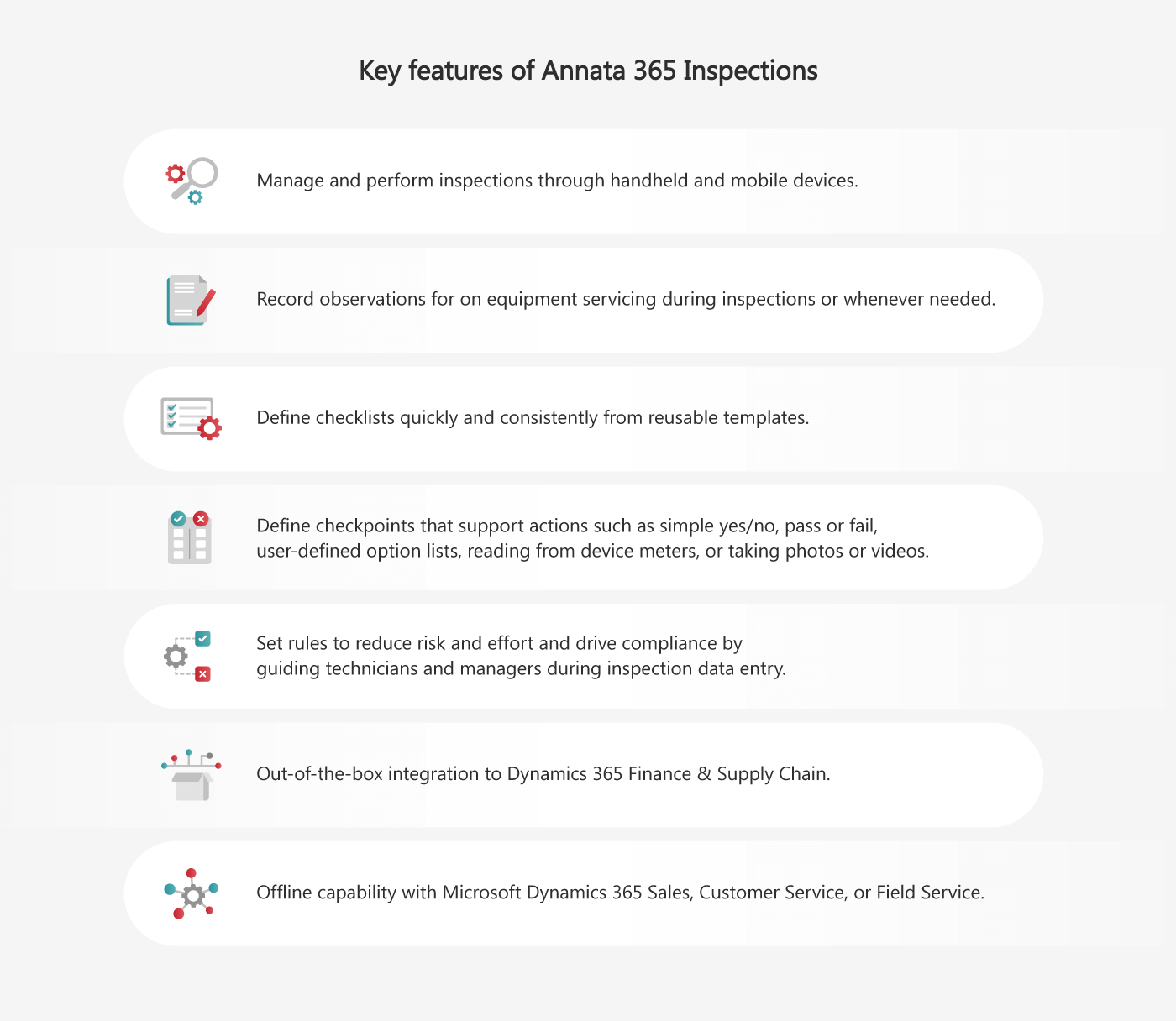

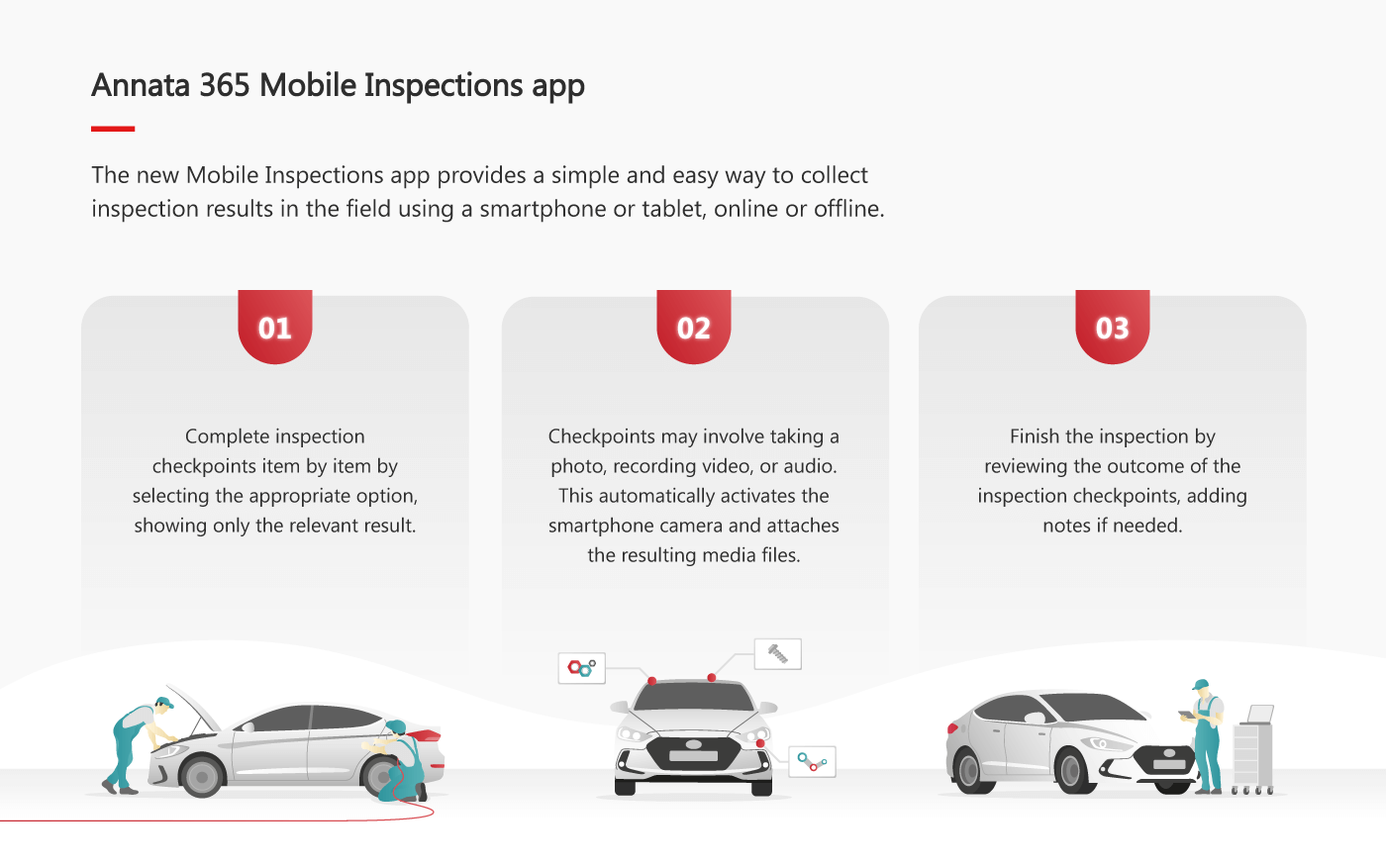

Annata 365 Inspections allows Dealerships and Service Centers to manage and perform inspections in import, sales, rental, and service for vehicles, heavy equipment, or other types of complex equipment.

Seamlessly integrated into the Annata 365 Sales and Annata 365 Field Service apps, this robust inspections app drives the digital transformation of online or offline inspection processes in the automotive and equipment industry, improving productivity and reducing cost.

Built on the Microsoft Power Platform and aligned with the Microsoft Common Data Model for Automotive, Annata 365 Inspections brings technical excellence, business insight, productivity, and compliance to the inspection process with minimal investment or risk.

Annata 365 Sales and Service integration

Annata 365 Sales includes …

- Validate a deal as such from an overall financial and process standpoint, following a checklist that does not refer to a device.

- Pre-delivery inspections for devices are easy to manage and run.

- Trade-in device inspections to check for faults and assess overall condition become a simple and managed data-driven process.

Annata 365 Field Service uses this …

- Service or safety inspection capability is seamlessly integrated and is set up and applied at the operation code level.

- Easy to use Play/Stop buttons to clock in or out of operations or to start inspections directly from the service order forms.

Connect with us to find out how Annata can power efficiencies for your automotive service center.

More information on Annata’s solutions is available here.