As customer demand continues to rise and the service process becomes more complex, companies rely on more than their technological capabilities to deliver exceptional results. So, what trends should the industry look at when devising its strategies for the new year? In this blog post, we’ll examine 5 key industry trends and what they mean for businesses in the equipment sector looking to boost efficiency, profitability, productivity, and competitiveness.

Looking ahead to 2023, the industrial equipment and machinery sector is at the forefront of industrial innovation with a particular focus on:

1. Tackling Supply Chain Traceability Head On

According to KPMG, investing in a cloud-based digital transformation strategy was a significant trend over the past year. Moreover, this trend is anticipated to accelerate in 2023 as firms adopt technology to mitigate their growing concerns about inflationary pressures and economic stagnation.

Companies will continue investing in digital traceability to gain comprehensive visibility of their assets and behaviour. End-to-end traceability simplifies fundamental processes, such as:

- Enhancing distributor inventory management

- Streamlining product recalls, assisting with regulatory compliance

- Achieving sustainability objectives and communicating product validity to end consumers.

This information can then be used to generate scenarios, make predictions, and dynamically improve operations. With this knowledge at their fingertips, leadership teams can better serve consumers, spot wasteful resource use, react to demand changes more quickly, and efficiently complete orders. In addition to this, they can recognize strategic value chain opportunities, innovate at a quicker rate, reduce the effects of internal and external disruptions, and ensure environmentally responsible processes and products.

Annata 365 represents technology that improves traceability, such as tracking each raw material used in the creation of a product and how machines are consumed, and where it is disposed of after use. Investing in such technology, building redundancies into your supply chain, considering new suppliers, sourcing options, and developing ecosystem partnerships are clever ways to withstand the worst disruptions and create a more resilient supply chain. Annata 365 for Device Management lets you efficiently track, trace and manage parts for increased supply chain visibility.

2. Modernizing Customer Service

Consumer-to-manufacturer models are reshaping the manufacturing industry. Instead of approaching consumers with their ready-made products, businesses can respond to established, consolidated, consumer-driven demand and offer customized products at lower prices.

Big data and the adoption of advanced analytics are driving forces behind this change. Manufacturers can better understand consumer needs and preferences by collecting data from physical assets, sales, services, and supply chains, allowing for more efficient and directed product development. Furthermore, real-time feedback on demand for a specific customized product improves manufacturing efficiency and significantly impacts customer acquisition costs, demand prediction, and production waste.

Annata 365 for Sales will enable sales teams to manage complex relationships more effectively and efficiently. This allows dealerships to gain new customers, maintain accurate customer information, and provide the best service possible. As a result, businesses across the value chain will increase productivity and sales while delivering quality service and creating new experiences based on 360° customer knowledge.

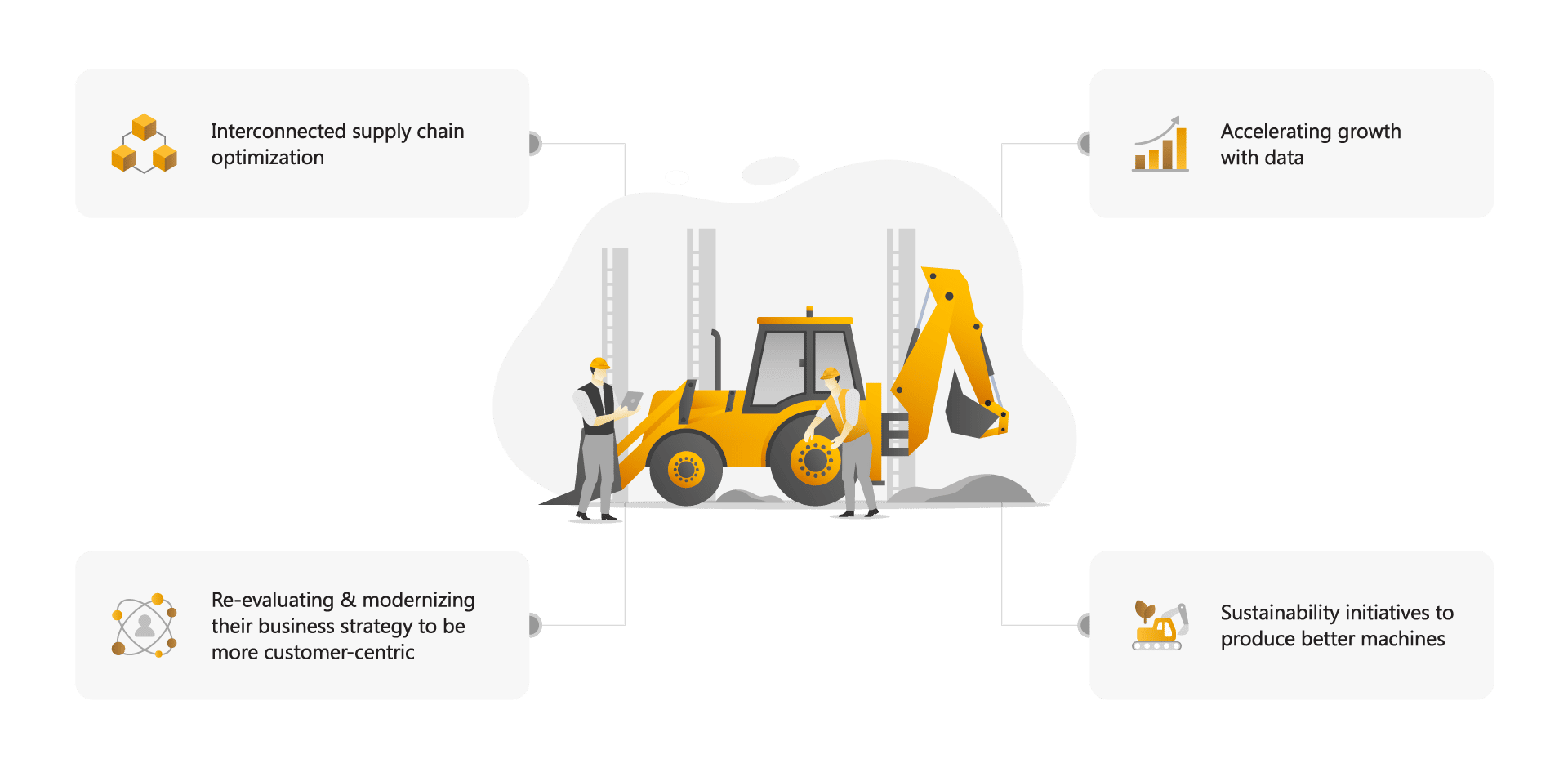

3. Designing for Circularity

With the transition of machinery manufacturers to new business models such as servitization, customers receive equipment and replacement parts and a dedicated maintenance service for their ownership. Increasing equipment durability and supporting an aftermarket spares business are critical factors to consider when implementing this strategy. The goal is to eliminate the need for replacement parts and repairs, which are typically the manufacturer’s responsibility. As a result, manufacturers are more concerned with preserving the functionality of their assets and maintaining a consistent cash flow, which requires a wealth of historical data to satisfy these criteria:

- Designing for life– Focusing on areas of the product that could fail by implementing superior design concepts.

- Designing for repair– Designing products that can be repaired quickly and easily.

- Designing for re-X– Using the waste hierarchy in the design process to remove, reduce, reuse, remanufacture/repair, recycle, and recover materials and parts while keeping ownership and value.

As a necessary step toward achieving sustainability goals, businesses must identify and eliminate operational bottlenecks. ERP systems have proven beneficial for automated audits and compliance reports, allowing for identifying the cause and severity of compliance violations. With available data in hand, they consult and observe customers, suppliers, and other stakeholders in the value chain and use these insights to generate innovative ideas for enhancement. However, only a few OEMs have the technological resources to effectively analyze this data to support revenue models centered on product design insights and maximum uptime.

Annata 365’s seamlessly integrated solutions, powered by Microsoft Dynamics 365, empower employees in the office and in the field with next-generation technology to provide visibility at every level of the equipment value chain, driving efficiency and increasing bottom lines. Businesses can then balance both sides of the circular economy equation – social responsibility and competitive advantage – designing new products, redesigning existing offerings, managing and servicing assets efficiently, or running uninterrupted production. Click here to learn how equipment OEMs can leverage valuable data to adopt circular economy initiatives.

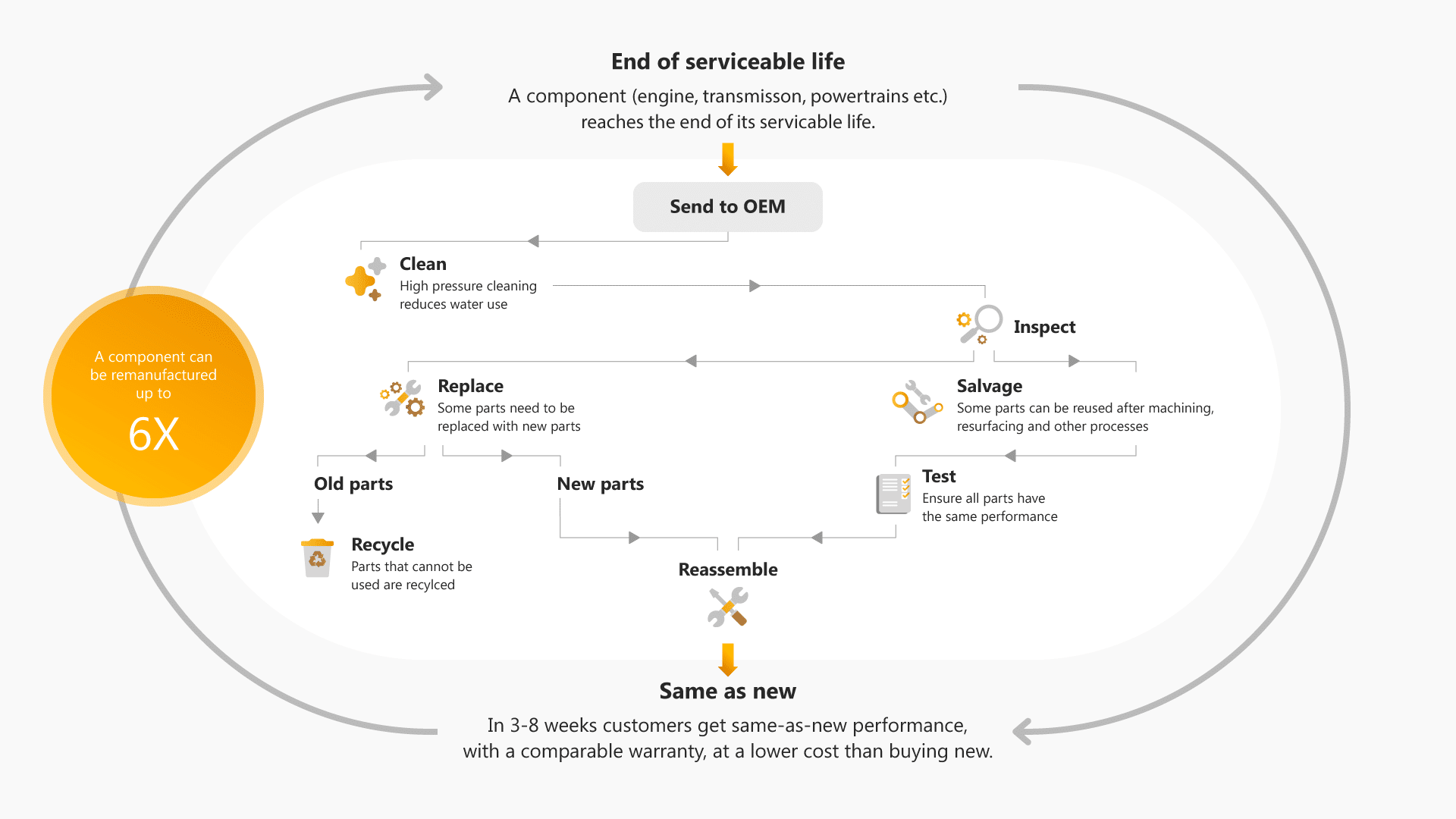

4. IoT – A Major Connectivity Trend

Most manufacturers have already incorporated IoT into essential business processes, such as logistics, employee and customer experience, predictive maintenance, and asset management. Aside from these applications, the servitization trend has solidified IoT’s place as a leading trend. However, to fully realize the potential of IoT with ERP, the ERP system must be adaptive, built on modern, cloud-based architecture, allowing for real-time data exchange to accommodate IoT inputs.

The best ERP solutions, such as Annata 365 Service, prioritize analytics to enable anywhere-accessible, real-time connectivity to IoT platforms. It begins with operator- and technician-friendly dashboards easily accessible via PC, mobile, or all portable devices, from any location. Because alerts in a real-time IoT system are frequently sent with prescriptive and analytic data before a problem develops, managers and technicians can prevent issues from wherever they are located.

5. Finding meaning in Big Data

In the past, managing a fleet meant using a master ledger, whiteboards, and map pins. This information exchange can be done with the right data management platform, which accurately represents how often machines are used, how much they cost to run and maintain, who runs them, and a host of other information that helps managers make the best decisions for their businesses. In addition, companies that obtain external data from third parties may look for financial partners who can use this information directly and give feedback to improve the data quality. As a result, customers will be steered toward purchasing or renting more efficient equipment based on equipment health or usage or even given better financing terms based on their credit history.

This information enables the end user and capital providers to make more informed decisions by sharing information about the asset’s life. This is yet another way the user, the manufacturer, and the finance company can all become more effective partners. Learn more about Business Intelligence & Analytics with Annata 365.

We think digital disruptions will be massive in 2023, with OEMs, manufacturers, and dealerships embracing new ways to make building and using machines more efficient, aggressively pursuing growth strategies, and getting the best business results possible.

Contact Annata today to develop a more integrated and scalable approach to incorporating these and other significant industry trends into your equipment business.